Our Services

Structural Engineering

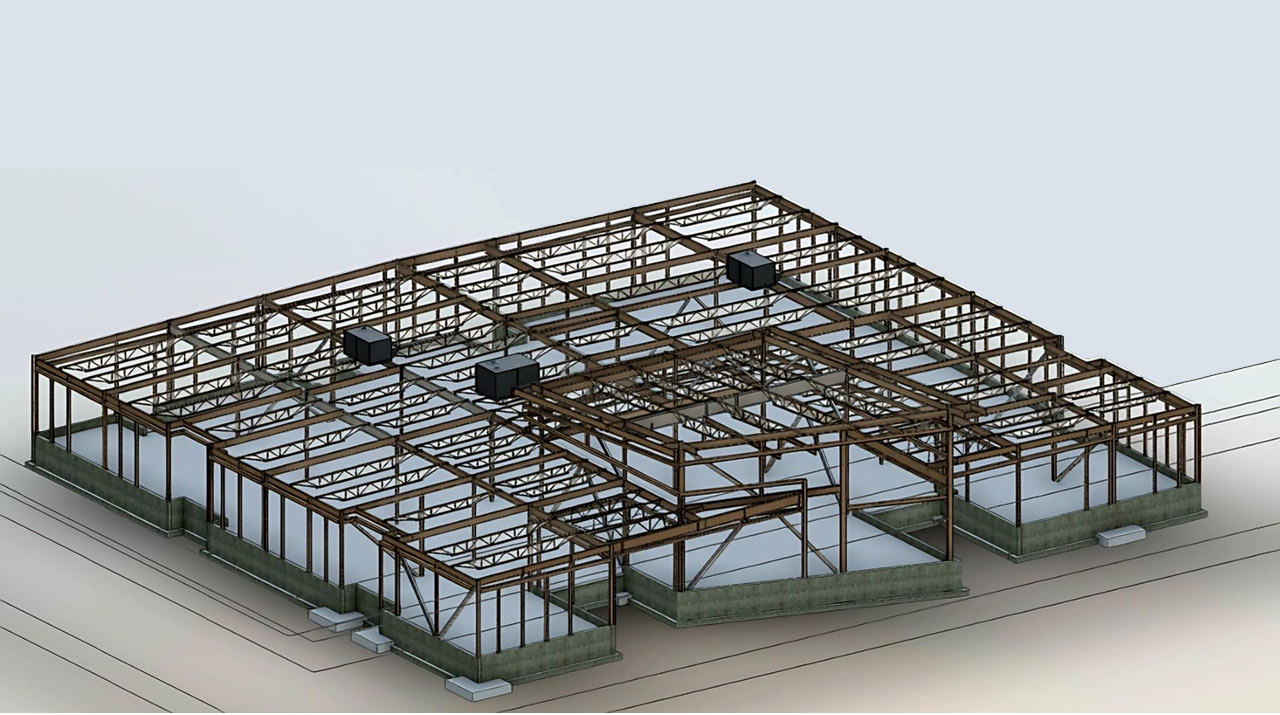

Structural Engineering & Value Engineering

Klondike Welding Ltd. is a firm registered to practice engineering in both Yukon and Alberta, offering a complete range of structural and welding engineering services. Our team develops project-specific Welding Procedure Data Sheets (WPDS) in compliance with CSA W59-24 and CSA W47-19 standards, ensuring every weld meets the highest quality and safety requirements.

We regularly act as the Engineer of Record (EoR) on steel structures and foundations, delivering design, analysis, and certification for both new builds and structural modifications. On projects where we are not the EoR, we provide specialized support in connection design and value engineering—working alongside the lead structural engineer to optimize constructability, reduce steel tonnage, and help bring projects in line with budget expectations.

Whether we’re leading the engineering or collaborating as part of a broader team, Klondike Welding brings practical, cost-conscious insight to every phase of a project.

Fabrication

Streel Fabrication & Erection

Klondike Welding Ltd. offers complete fabrication and erection services under one roof—delivering seamless execution from shop to site. Our 13,000 sq ft fabrication facility is fully equipped with the tools and technology needed to produce high-quality structural steel with precision and efficiency. Key equipment includes a Machitech Diamond Cut plasma table powered by a Hypertherm XPR300, three overhead cranes, two band saws, a 50-ton ironworker, and multiple welding machines capable of GTAW, MCAW, FCAW, and GMAW processes. This setup allows us to fabricate everything from standard building components to complex custom assemblies in-house.

Quality is central to everything we do. Klondike Welding has a comprehensive in-house Quality Program led by a CWB Level 2 Welding Inspector. Every welded component leaving our facility is inspected, recorded, and approved before shipment. All inspection results are documented in detailed reports, which are submitted to clients as part of our commitment to transparency, traceability, and code compliance.

Once fabrication is complete, our in-house erection crew ensures safe, efficient steel installation. We own and operate our own lifting equipment, including a Manitex 40110 truck-mounted crane with a 48’ jib and a Genie S-125 aerial work platform (AWP). Our team of certified welders, riggers, and operators has extensive experience working in both urban and remote locations, giving us the flexibility to deliver even in the most logistically challenging environments.

We are proficient in delivering projects through a variety of construction methods, including:

- General Contracting

- Construction Management

- Design-Build

- Progressive Design-Build

In Progressive Design-Build, Design-Build, and Construction Management models, we are often brought in early as a trusted ally to assist with constructability reviews and budgeting. By collaborating closely with the design team during the early phases, we help identify practical, cost-effective solutions that streamline fabrication, reduce site challenges, and align the design with the project’s budget and schedule.

Regardless of the delivery method, our focus is always to find the best way to construct—optimizing schedule, improving efficiency, and maintaining the highest standards of quality.

Our fabrication and erection capabilities include:

- Structural beams, columns, and bracing

- Stairs, landings, and railings

- Custom welded assemblies and engineered connections

- Embedded components for cast-in-place concrete

- Sandblasting services and steel preparation to CISC/CPMA 2-75 standards

- Complete on-site steel erection with in-house crane and AWP support

By managing both fabrication and erection in-house, Klondike Welding eliminates coordination gaps, shortens schedules, and delivers a more streamlined, reliable construction experience from start to finish.

Bridge Rehabilitation & Reinforcement

Bridge Rehabilitation & Reinforcement

Klondike Welding Ltd. specializes in the structural rehabilitation and reinforcement of steel bridges. Whether it’s upgrading load capacity, repairing corrosion damage, or replacing critical components, we help extend the service life of aging infrastructure. Our team understands the importance of minimizing downtime and maintaining public safety—especially when working on active roadways. With proven experience in complex retrofits, tight staging conditions, and custom access solutions, we deliver efficient, durable results tailored to each bridge’s unique challenges.

To date, we have successfully delivered rehabilitation work on more than 20 bridges across the Yukon. For each project, we develop a comprehensive Project Management Plan tailored to the scope and site conditions. This includes a detailed Traffic Management Plan to safely accommodate public use, a Risk Management Plan addressing site-specific hazards and logistics, and a complete Job Hazard Analysis (JHA) for all critical tasks before work begins. These plans are created in collaboration with our field crews, engineers, and safety advisors to ensure practical, effective execution in complex environments.

Our bridge services include:

- Structural steel repairs and retrofits

- Reinforcement of existing members for increased load capacity

- Replacement of corroded or damaged steel components

- Jacking of bridges and replacement of bearings

- Installation of new steel elements for structural upgrades

- Custom scaffold design and installation for safe access beneath bridges

- Safe traffic staging and accommodation on active roadways

- Compliance with CSA and Ministry of Transportation standards

With certified welders, experienced field crews, and a focus on safety and precision, Klondike Welding delivers dependable bridge solutions that stand the test of time.